PICCINI MARMI PREGIATI

For over 40 years we have been shaping natural stone with unmitigated passion and deep admiration for the original splendour of this material. We convey its unique value in every project we carry out, so that each one bears the characteristics and features of a style that is unmistakeably Italian.

A LONG ITALIAN TRADITION OF PASSION AND EXCELLENCE

A passion for natural stone, and a long-standing tradition of Italian standards of excellence, are the main features of Piccini Marmi Pregiati. The company has been working and operating in Italy ever since its inception and is located in Massa Carrara, the extraction area renowned throughout the world for its excellent quality marble.

Years of experience in the world of architecture and International design has contributed prominently to the company’s growth, and every project undertaken highlights an innate taste for style and elegance, which today form an integral, fundamental part of its identity.

The company has always worked in perfect synergy with well-known architects and designers, in realizing ambitious, important architectural projects, where the original beauty and uniqueness of natural stone combined with skillful and experienced craftsmanship, give architectural design and interior ambiance a tone of exclusivity and timeless sophistication.The splendour of these materials, their colours and physical characteristics, allow designers great creative freedom and give rise to innovative solutions that enhance design, both in the context of new contemporary styles and when dealing with classical architectural projects.

Many important, prestigious projects in architecture and design such as public, commercial, luxury buildings and hotels and splendid, private villas, all over the world, bear the hallmark of Piccini Marmi Pregiati, the undisputed excellence of Italian expertise.

RELIABILITY ‘ AND SUBSTANCE – An exclusive turnkey service

The company has just the right structure designed to offer architectural firms an exclusive turnkey service, complete from project consulting and technical solutions, through to supplying materials and handling all requests, even the most challenging. Once an order has been placed, Piccini Marmi then proceeds to source material, by searching, selecting and acquiring the most valuable stone directly from the original quarries, even for large scale job orders, for which we guarantee consistency and uniformity.

Mock-up presentations

After the company has purchased all the raw and semi-finished materials needed for a project, they are placed in storage facilities in preparation for a mock-up presentation, and to undergo a selection process with architects and clients. All materials are screened and selected for approval.

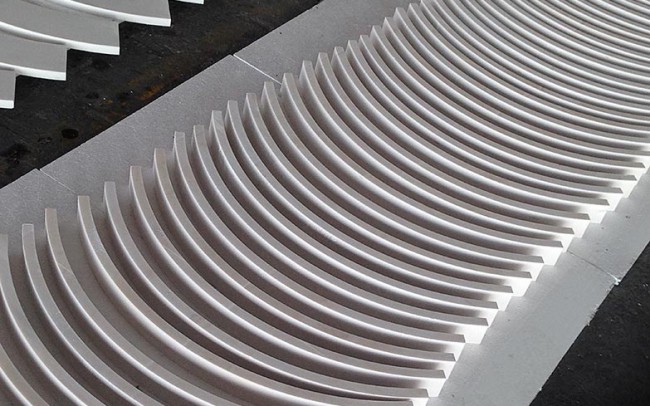

Controlling each processing stage

In the subsequent stages the whole production process gets underway. All processing is carried out in Italy by expert marble masons and craftsmen, combining the wisdom of ancient craft techniques with advanced numerical control technology, creating an indissoluble union between tradition and innovation. The high automation level of the production process allows for the cutting and machining of solid blocks, to make architectural and design elements such as sinks, washbasins, bathtubs, frames, bas-reliefs, stairs, as well as other processes and finishes using waterjet cutting.

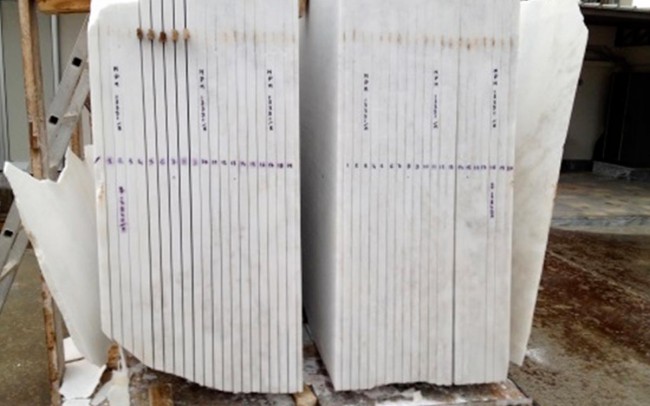

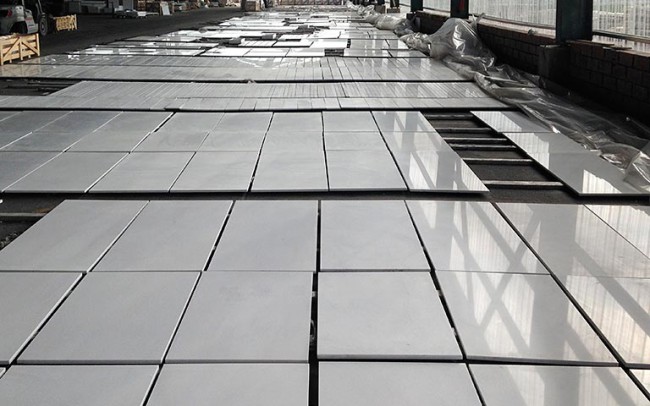

Dry setting

To complete the process in the pre-installation stages is the dry-setting, blending and matching of all selected, finished material. All cladding and covering stone is meticulously assembled to achieve the right aesthetic blend of color, shading, and perfectly book-matched patterns and veining, as well as to ensure each solid element fits perfectly. Waterjet cut medallions and inlays are also dry laid. Architects and project managers are on-site to check and verify the process.

Packing and Shipping

The packing stages are extremely important since all the finished materials, before being packed in wooden crates, are numbered in sequence to ensure final installation as established in the dry setting stage. Once packing is complete, the shipping manager will see that the crates are loaded into containers for shipment to the building site.